The servodisc motor is also often called a _____ motor. – The servodisc motor, also commonly known as a pancake motor or flat motor, stands as a unique and versatile electromechanical device that finds widespread application in various industries. This comprehensive guide delves into the intricacies of servodisc motors, exploring their function, design, control, advantages, and potential future advancements.

With its compact size, high torque density, and exceptional precision, the servodisc motor has become a cornerstone of modern automation systems. Its unique characteristics make it ideally suited for applications requiring precise motion control, such as robotics, medical devices, and industrial machinery.

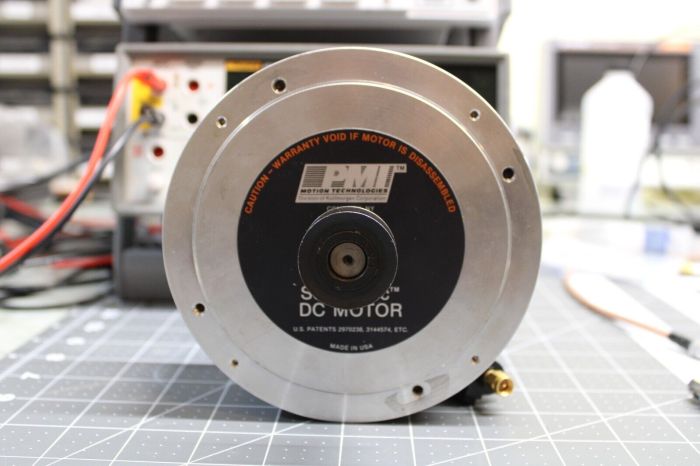

Define the Servodisc Motor

A servodisc motor, also known as a torque motor, is a type of electric motor that provides precise control over speed, torque, and position. It consists of a rotating disc or armature that is sandwiched between two stator windings. The stator windings are energized to create a magnetic field that interacts with the armature, producing torque and causing the disc to rotate.

Synonyms for Servodisc Motor: The Servodisc Motor Is Also Often Called A _____ Motor.

- Torque motor

- Pancake motor

- Disc motor

The term “servodisc motor” is commonly used in industrial automation and motion control applications, while “torque motor” is often used in robotics and high-performance servo systems.

Applications of Servodisc Motors

Servodisc motors are widely used in various industries and applications due to their high precision, torque density, and dynamic response. Some common applications include:

- Robotics

- Motion control systems

- Industrial automation

- Medical equipment

- Aerospace applications

Design and Construction of Servodisc Motors

A typical servodisc motor consists of the following key components:

- Rotating disc or armature

- Two stator windings

- Permanent magnets

- Rotor position sensor

The armature is made of a conductive material, such as copper or aluminum, and is typically disc-shaped. The stator windings are wound around the armature and are energized to create a magnetic field. Permanent magnets are used to provide a constant magnetic field, which interacts with the armature to produce torque.

Control and Operation of Servodisc Motors

Servodisc motors are typically controlled using a closed-loop control system. The rotor position sensor provides feedback to the controller, which compares the actual position to the desired position and adjusts the motor’s torque and speed accordingly.

There are different types of control systems used for servodisc motors, including:

- Proportional-integral-derivative (PID) control

- State-space control

- Model-based control

Advantages and Disadvantages of Servodisc Motors

Advantages:, The servodisc motor is also often called a _____ motor.

- High precision and accuracy

- High torque density

- Fast dynamic response

- Compact and lightweight

- Low maintenance

Disadvantages:

- Higher cost compared to other types of motors

- Limited speed range

- Can be sensitive to environmental factors

Future Trends in Servodisc Motor Technology

Emerging trends in servodisc motor technology include:

- Development of new materials and designs to improve performance and efficiency

- Integration of advanced control algorithms and sensors

- Exploration of new applications in fields such as robotics and medical devices

FAQ Overview

What is the primary function of a servodisc motor?

A servodisc motor is primarily used for precise motion control in various applications, such as robotics, medical devices, and industrial machinery.

What sets servodisc motors apart from other types of motors?

Servodisc motors are distinguished by their compact size, high torque density, and exceptional precision, making them ideal for applications requiring accurate and controlled motion.

What are the key advantages of using servodisc motors?

The advantages of servodisc motors include their compact size, high torque density, low inertia, and ability to deliver precise motion control with high repeatability.

What industries commonly utilize servodisc motors?

Servodisc motors are widely used in robotics, medical devices, industrial automation, semiconductor manufacturing, and aerospace applications.