Delve into the intricate anatomy of a chainsaw chain, a pivotal component in the forestry industry. Discover the various types of chains available, each meticulously engineered to conquer diverse cutting challenges.

From drive links to cutters and tie straps, we’ll dissect the essential components that orchestrate the chain’s cutting prowess. Explore the nuances of full chisel, semi-chisel, and chipper chains, unraveling their strengths and limitations.

Introduction

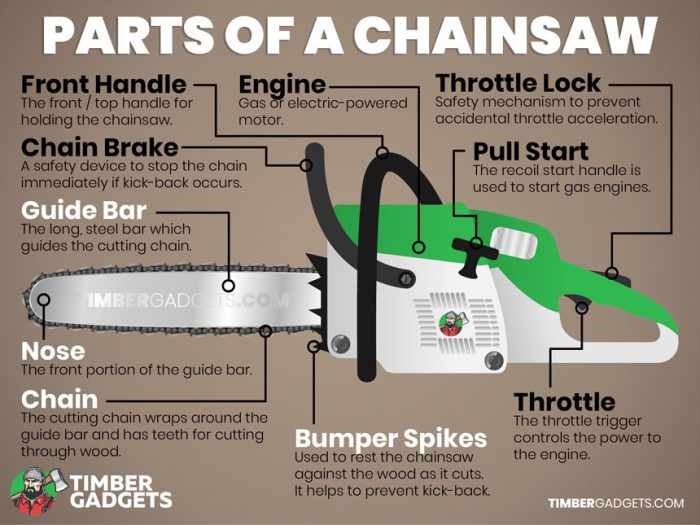

Chainsaws are essential tools in the forestry industry, used for felling trees, cutting firewood, and other forestry tasks. The chainsaw chain is a critical component of the chainsaw, and its design and construction directly impact the performance and efficiency of the saw.

There are various types of chainsaw chains available, each designed for specific applications and cutting conditions. The choice of the right chain depends on factors such as the type of wood being cut, the size and power of the chainsaw, and the desired cutting performance.

Types of Chainsaw Chains

- Full-chisel chains:These chains have sharp, chisel-shaped teeth that provide aggressive cutting action. They are ideal for cutting hardwoods and frozen wood.

- Semi-chisel chains:These chains have teeth with a rounded cutting edge. They are less aggressive than full-chisel chains but provide a smoother cut and are less prone to kickback.

- Skip chains:These chains have teeth arranged in a skip pattern, with every other tooth removed. They are designed for cutting softwoods and provide a fast, efficient cut.

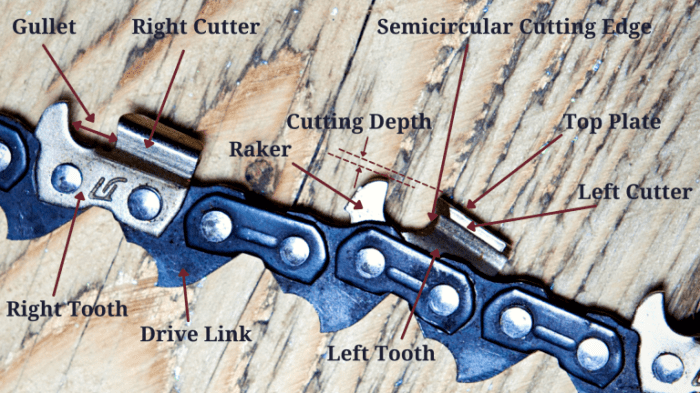

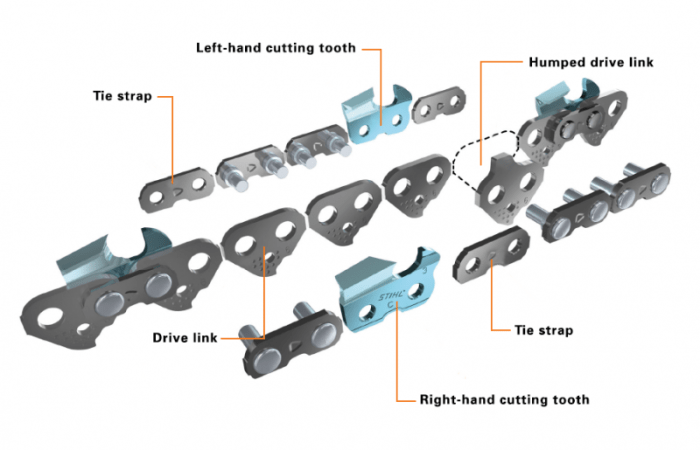

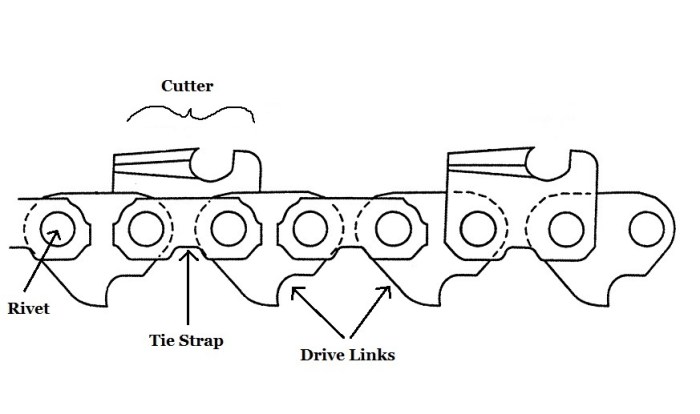

Components of a Chainsaw Chain: Anatomy Of A Chainsaw Chain

A chainsaw chain is a critical component of the chainsaw, consisting of several essential parts that work together to cut through wood efficiently. These components include drive links, cutters, and tie straps, each playing a specific role in the cutting process.

Drive Links

Drive links are the backbone of the chainsaw chain, connecting the different components and providing the power to drive the chain around the guide bar. They have a unique shape that engages with the drive sprocket on the chainsaw, allowing the chain to move smoothly and consistently.

Cutters

Cutters are the teeth of the chainsaw chain, responsible for cutting through the wood. They are made of hardened steel and feature sharp cutting edges that slice through wood fibers. Cutters come in various shapes and sizes, designed to handle different types of wood and cutting conditions.

Tie Straps

Tie straps are the connecting elements that hold the drive links and cutters together. They are typically made of steel and are designed to withstand the high forces generated during cutting. Tie straps ensure that the chain remains intact and maintains its shape while in operation.

Types of Chainsaw Chains

Chainsaw chains come in a variety of types, each designed for specific cutting applications and performance requirements. Understanding the differences between these types will help you select the right chain for your chainsaw and cutting needs.

Full Chisel Chains

- Full chisel chains have teeth with sharp, square-edged cutters that remove wood aggressively.

- Advantages: Fast cutting, ideal for hardwoods and frozen timber.

- Disadvantages: Higher risk of kickback, requires more sharpening.

Semi-Chisel Chains, Anatomy of a chainsaw chain

- Semi-chisel chains feature teeth with slightly rounded cutters that provide a balance between cutting speed and durability.

- Advantages: Less kickback, longer lifespan than full chisel chains.

- Disadvantages: Slower cutting, may not be suitable for hardwoods.

Chipper Chains

- Chipper chains have teeth with small, rounded cutters that are designed to create a smooth, finished cut.

- Advantages: Minimal kickback, excellent for cross-cutting and finish work.

- Disadvantages: Slower cutting, not ideal for heavy-duty applications.

Factors to Consider When Choosing a Chainsaw Chain

When selecting a chainsaw chain, it’s crucial to consider several key factors that influence its performance and suitability for specific cutting tasks. These factors include:

Type of Wood Being Cut

The hardness and density of the wood being cut significantly impact the chain’s design and performance. Chains designed for softwoods, such as pine and cedar, typically feature shallower cutting angles and wider cutters to facilitate fast and efficient cutting. Conversely, chains intended for hardwoods, like oak and maple, require steeper cutting angles and narrower cutters to penetrate denser wood fibers effectively.

Size and Power of the Chainsaw

The size and power of the chainsaw determine the appropriate chain pitch and gauge. Pitch refers to the distance between drive links, while gauge indicates the thickness of the drive links. Larger and more powerful chainsaws require chains with larger pitch and gauge to handle the increased cutting forces.

Mismatching the chain size to the chainsaw can lead to premature wear, reduced cutting efficiency, or even damage to the chainsaw.

Desired Cutting Performance

Consider the desired cutting performance when choosing a chain. Chains with a higher number of cutting teeth per inch (TPI) provide smoother cuts but may be less aggressive in dense wood. Conversely, chains with fewer TPI offer more aggressive cutting but may produce rougher cuts.

The appropriate TPI depends on the specific cutting application and the user’s preference for speed or precision.

The anatomy of a chainsaw chain is a complex system of cutters, rakers, and drive links. Just like an advocate of a lawless state , each component plays a crucial role in maintaining the chain’s efficiency and safety. The cutters are responsible for severing the wood fibers, while the rakers control the depth of the cut.

The drive links connect the chain to the chainsaw’s power source, ensuring smooth operation.

Maintenance of Chainsaw Chains

Proper maintenance of your chainsaw chain is crucial to ensure optimal performance and longevity. Neglecting regular care can lead to premature wear, decreased cutting efficiency, and potential safety hazards.

To maintain your chainsaw chain, you should focus on three key aspects: sharpening, cleaning, and lubrication.

Sharpening

A sharp chainsaw chain is essential for efficient cutting. Over time, the teeth of the chain will become dull, which will require sharpening to restore their sharpness. You can sharpen the chain using a variety of tools, such as a file or a chainsaw sharpener.

If you are not comfortable sharpening the chain yourself, you can take it to a professional for assistance.

Cleaning

Keeping the chainsaw chain clean is equally important as sharpening. Debris such as sawdust, dirt, and oil can accumulate on the chain, which can interfere with its performance and cause premature wear. To clean the chain, you can use a brush or a compressed air hose to remove any loose debris.

You can also soak the chain in a cleaning solution to remove stubborn dirt and oil.

Lubrication

Lubricating the chainsaw chain is essential to reduce friction and wear. Without proper lubrication, the chain will overheat and become damaged. You can lubricate the chain using a variety of lubricants, such as bar oil or chainsaw oil. It is important to follow the manufacturer’s recommendations for the type and frequency of lubrication.

Troubleshooting Chainsaw Chain Problems

Chainsaw chains can encounter various issues during operation, affecting their performance and safety. Identifying and addressing these problems promptly is crucial for maintaining an efficient and safe chainsaw.

Chain Stretching

Chain stretching is a common problem that occurs when the chain is not properly tensioned or lubricated. An excessively stretched chain can slip off the sprocket or bind, causing damage to the chainsaw.

To solve this problem, follow these steps:

- Adjust the chain tension according to the manufacturer’s recommendations.

- Lubricate the chain regularly with a high-quality chain oil.

- Inspect the chain for wear and replace it if necessary.

Chain Breakage

Chain breakage can be caused by excessive wear, impact with hard objects, or improper tension. A broken chain can be dangerous and should be replaced immediately.

To prevent chain breakage, follow these guidelines:

- Use a chain with the correct size and pitch for your chainsaw.

- Avoid cutting into hard objects such as rocks or metal.

- Maintain proper chain tension and lubrication.

Dull Cutters

Dull cutters reduce the efficiency of the chainsaw and can make cutting difficult. Cutting with dull cutters also increases the risk of kickback.

To sharpen dull cutters, follow these steps:

- Use a chainsaw sharpener or file to grind the cutters to the proper angle.

- Ensure that the cutters are all the same length and sharpness.

- Regularly check the sharpness of the cutters and sharpen them as needed.

Safety Precautions

Chainsaws are powerful tools that can be dangerous if not used properly. It is important to take the necessary safety precautions when using a chainsaw chain to prevent accidents and injuries.

One of the most important safety precautions is to wear proper protective gear. This includes a hard hat, eye protection, ear protection, gloves, and chaps. Protective gear will help to protect you from flying wood chips, sawdust, and other debris that can be generated when using a chainsaw.

Proper Clothing

- Wear snug-fitting, protective clothing made of strong material.

- Avoid loose clothing or jewelry that can get caught in the chain.

- Tuck in your shirt and pants to prevent them from getting caught.

Proper Footwear

- Wear sturdy, non-slip boots with steel toes to protect your feet from falling objects and cuts.

- Make sure the boots are comfortable and provide good ankle support.

Other Safety Precautions

- Never operate a chainsaw while under the influence of alcohol or drugs.

- Always inspect the chainsaw and chain before using it to make sure it is in good working condition.

- Never use a chainsaw that is not properly maintained.

- Keep the chainsaw chain sharp to reduce the risk of kickback.

- Always use a chainsaw with a chain brake.

- Be aware of your surroundings and be careful not to cut into anything that could cause the chain to kickback.

- Never cut above shoulder height.

- Always have a clear escape route in case the chainsaw kicks back.

By following these safety precautions, you can help to reduce the risk of accidents and injuries when using a chainsaw chain.

Key Questions Answered

What are the key components of a chainsaw chain?

Drive links, cutters, and tie straps form the core components, each playing a crucial role in the chain’s cutting action.

How do I choose the right chainsaw chain for my needs?

Consider the wood type, chainsaw size and power, and desired cutting performance to make an informed choice.

Why is proper chainsaw chain maintenance essential?

Regular sharpening, cleaning, and lubrication extend the chain’s lifespan, enhance cutting efficiency, and prevent premature wear.